The Quality Assurance approach at Marvel Medtech Advanced Manufacturing follows a systematic method of defining and documenting requirements, then developing, verifying and validating processes to meet those requirements, then providing on-going documented evidence that processes are capable, stable, predictable, and reliable in reproducing results that conform to requirements and expectations. The aim of Quality Assurance at Marvel Medtech Advanced Manufacturing is to meet or exceed our customer’s requirements and expectations, and to comply with the relevant U.S. and international standards for quality management systems in the industry segments we serve.

Features of Our Quality Management System

As a subcontract manufacturer of advanced technical ceramic components designed by our customers, using XJet Nanoparticle Jetting™ 3D Printing / Additive Manufacturing technology, Marvel Medtech Advanced Manufacturing relies upon and works closely with our customers to ensure requirements are well-defined and understood within the context of the NPJ™ system capabilities. This frequently entails providing Design for Additive Manufacturing (DFAM) guidance to our customers to achieve optimal results from a part design and performance perspective, as well as production efficiency perspective.

Quality planning with the customer results in a Validation and Verification (V&V) Plan that entails review, re-execution and re-documentation—as appropriate—of Marvel Medtech Advanced Manufacturing’s Installation Qualification (IQ), Operational Qualification (OQ) and Performance Qualification (PQ) protocols for each unique customer application.

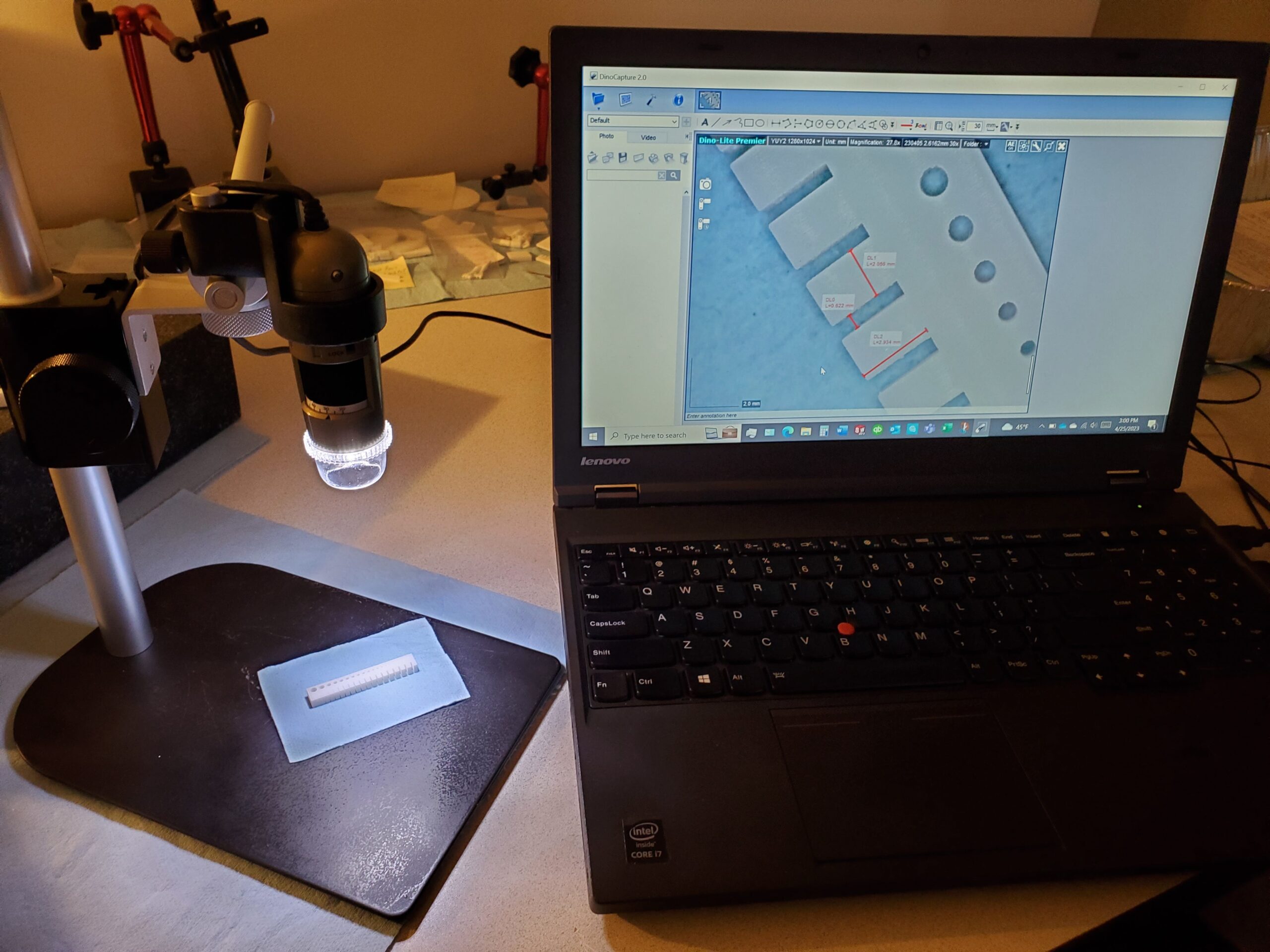

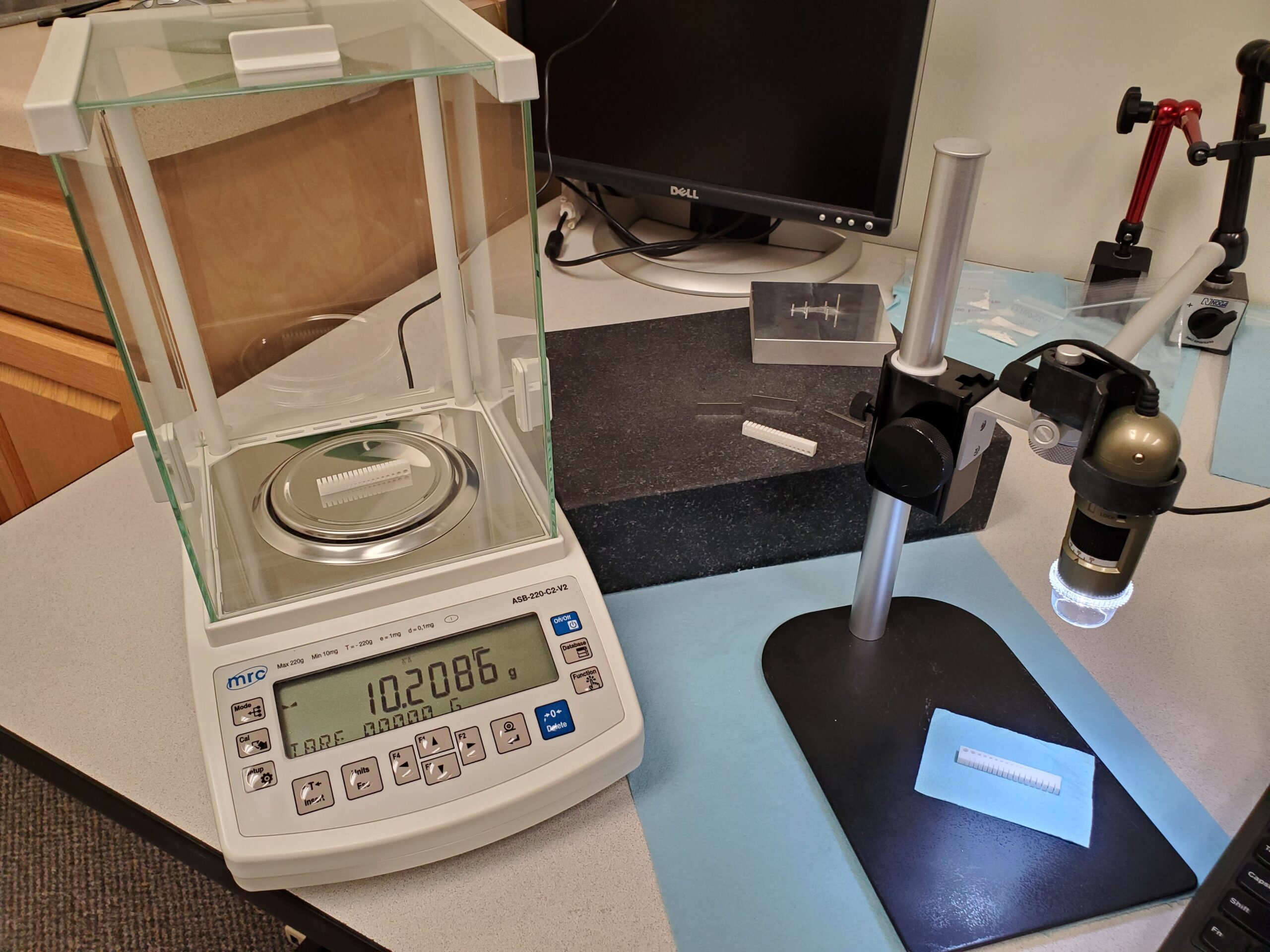

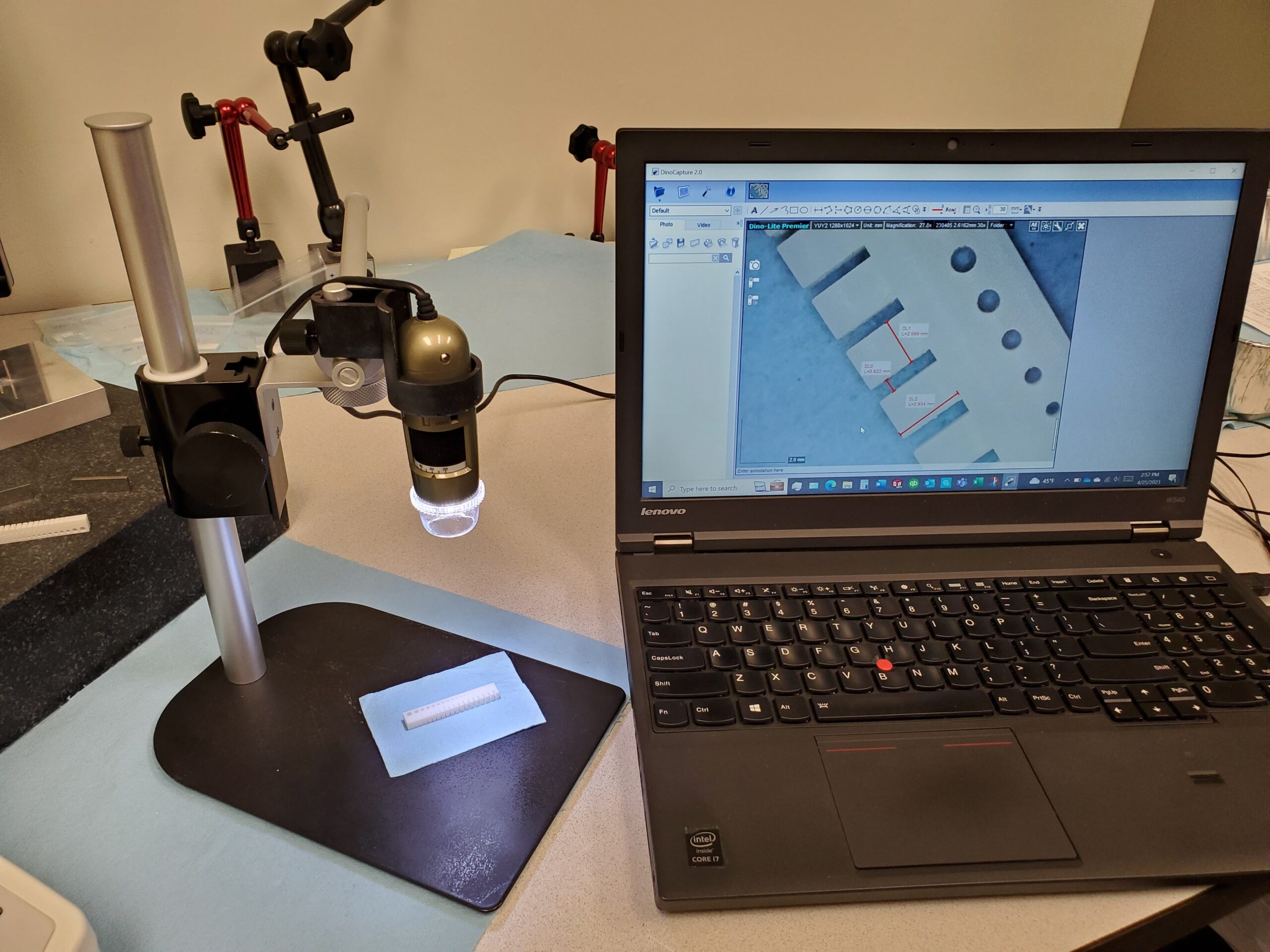

After DFAM design modifications (if necessary) are implemented, tested (if necessary), and approved by the customer, and the V&V plan has been developed and approved, Marvel Medtech Advanced Manufacturing’s team monitors and documents key production process variables at all stages of the AM process. Upon completion, finished parts are inspected and tested as per the V&V plan.

Do you want to know more about our advanced technical ceramics additive manufacturing quality assurance processes and controls? Please contact our team at 1-877-345-6261 or 1-608-688-0868. Or you can Request a Quote for Your Project to receive a secure file upload link and start a discussion with our team about your advanced technical ceramics AM project.