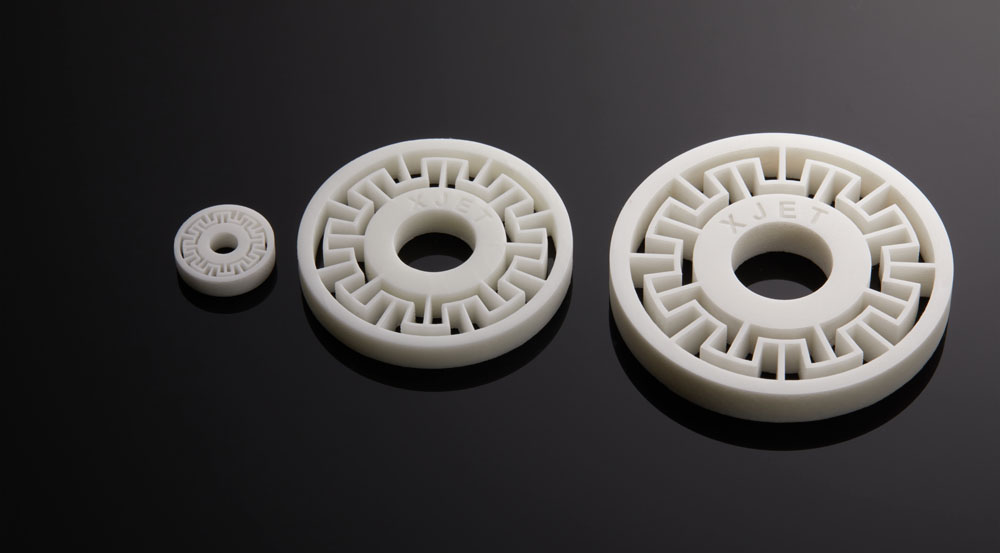

One of the key benefits of the AM approach is the capability to produce prototypes of your advanced technical ceramics part designs very quickly without requiring a large investment in specialized tooling. All that is required is a 3D solid model of your design and Marvel Medtech Advanced Manufacturing’s unique expertise in using the XJet NPJ™ system for AM of challenging part designs. With our Design for Additive Manufacturing (DFAM) know-how, we can help you optimize your part design for best AM results and production efficiencies.

It doesn’t matter whether you need functional prototypes to validate the authenticity of your designs, or concept models to guide your development decisions; we can help you with both. We can typically even produce several different design variation of technical ceramic prototypes in the same production run, again without requiring an investment in specialized tooling, very quickly and cost-effectively. Rapid technical ceramics prototyping services from Marvel Medtech Advanced Manufacturing will equip you to test and refine your product ideas and get to the market faster than your competitors with minimal up-front investment.

Workflow in Rapid Technical Ceramic Prototyping at Marvel Medtech Advanced Manufacturing

- Solid Model Development of your design: Visit our Request a Quote for Your Project page to request a secure link to upload your solid model file

- Our experienced AM engineers can provide DFAM (Design for Additive Manufacturing) guidance as you refine your part design.

- We use Solidworks™ for our solid model engineering, so SLDPRT format files are preferred. We also accept other solid model formats such as STP / STEP.

- Our engineers will evaluate the design for optimum AM compatibility. We will provide appropriate alternative suggestions to maximize AM results and efficiency, accelerate your time-to-market, and minimize production costs.

- Depending on the configuration of your design, we may need to add AM fixturing or support structures to your part to optimally position it on the print tray.

- Print Tray Layout Configuration:

- Placement of part(s) on the print tray is configured for optimum AM results and cost efficiency.

- Depending on part size, a print tray may include multiple copies of the same part, several different parts, or several different design variations of a prototype concept for more rapid assessment of your design ideas.

- Preliminary pricing: Once the tray layout is configured, preliminary pricing can be determined.

- Prototype AM Production: Upon final customer approval, the print tray is schedule for AM production.

- 3D Printing: The size of the parts on the tray determines the AM production time required to 3D print the parts.

- Part cleaning: Upon completion of the 3D printing, the parts are placed in a controlled water bath to dissolve-away the support material. No additional post-processing is required to remove printed supports or fixtures. When clean, parts are allowed to air-dry for 24-48 hours, depending on part size and configuration.

- Sintering: “Green” 3D printed parts are sintered “in air” in a furnace at typical ceramics sintering temperatures: 1400-1450C for Zirconia and 1700C for Alumina.

- Evaluation: The fully sintered technical ceramic prototype parts are tested per the customer’s requirements, then sent to the customer for assessment.

Benefits of Rapid Technical Ceramic Prototyping with Ceramics Additive Manufacturing / Ceramics 3D Printing

- Cost effective: Technical ceramics prototyping with AM can be done very quickly with no up-front investment in specialized tooling. Multiple prototype design variations can be produced and evaluated concurrently, again with no up-front tooling costs.

- Improved Development Times: 3D printing is inherently a quick turn-around manufacturing approach, going from CAD solid model to fully-sintered finished part in a matter of a few days. The flexibility of printing several different prototype design variations on the same print tray can save weeks or even months of development time.

- Design Flexibility: 3D printing enables a whole new paradigm of design freedom and flexibility. There is virtually no limitation on part geometries and feature complexity that can be included in part designs, enabling fabrication of complex parts that cannot be made in one piece by legacy ceramics manufacturing methods.

- Profitability: Cost effectiveness, improved development times, and greater design flexibility offer the opportunity for better profitability for many development projects with AM rapid prototyping of your advanced technical ceramics designs.

Materials Available for Technical Ceramics Prototyping

The following advanced technical ceramics materials are currently available for rapid ceramics prototyping with ceramics additive manufacturing / ceramics 3D printing:

- Zirconia: TZ-3Y (Tetragonal Zirconia Oxide (ZrO2) partially stabilized with 3 Mol percent Yttria (Y2O3)) – A commonly used formulation known for its high compressive strength, high flexural strength and high fracture toughness.

- Alumina: High-purity (99.9+ %) Alumina Oxide (Al2O3) – Commonly used in high temperature and electrical insulation applications.

| Material | Zirconia (ZrO2) | Alumina (Al2O3) |

| Density (g/cc) | 6.02 | 3.92 |

| Hardness (GPa) | 12.7 | 14.5 |

| Flexural Strength (MPa) | 1240 | 430 |

| Fracture Toughness (MPa/m) | 13 | 4-5 |

| Thermal Conductivity (W/mK) | 2.2 | 37 |

Applications of Rapid Ceramic Prototyping

Rapid ceramic prototyping may be effectively employed for:

- Functional prototypes

- Concept models

- Production molds for prototyping other materials

- Production tool prototypes

- Pre-production/engineering prototypes

Contact Marvel Medtech Advanced Manufacturing for Your Advanced Technical Ceramics Additive Manufacturing / Ceramics 3D Printing Rapid Ceramic Prototyping Needs

Our unique expertise in using the XJet NPJ™ ceramics additive manufacturing / ceramics 3D printing technology enables us to handle the most demanding development challenges for rapid ceramics prototyping. Our ceramics additive manufacturing services / ceramics 3D printing services offering entails working closely with you to understand your application requirements and provide guidance on optimizing part designs for best ceramics additive manufacturing / ceramics 3D printing results. Please visit our Request a Quote for Your Project page to receive a secure link for uploading your solid model file for our review, or contact us at 1-877-345-6261 or 1-608-688-0868 with your questions on advanced technical ceramics AM rapid prototyping.