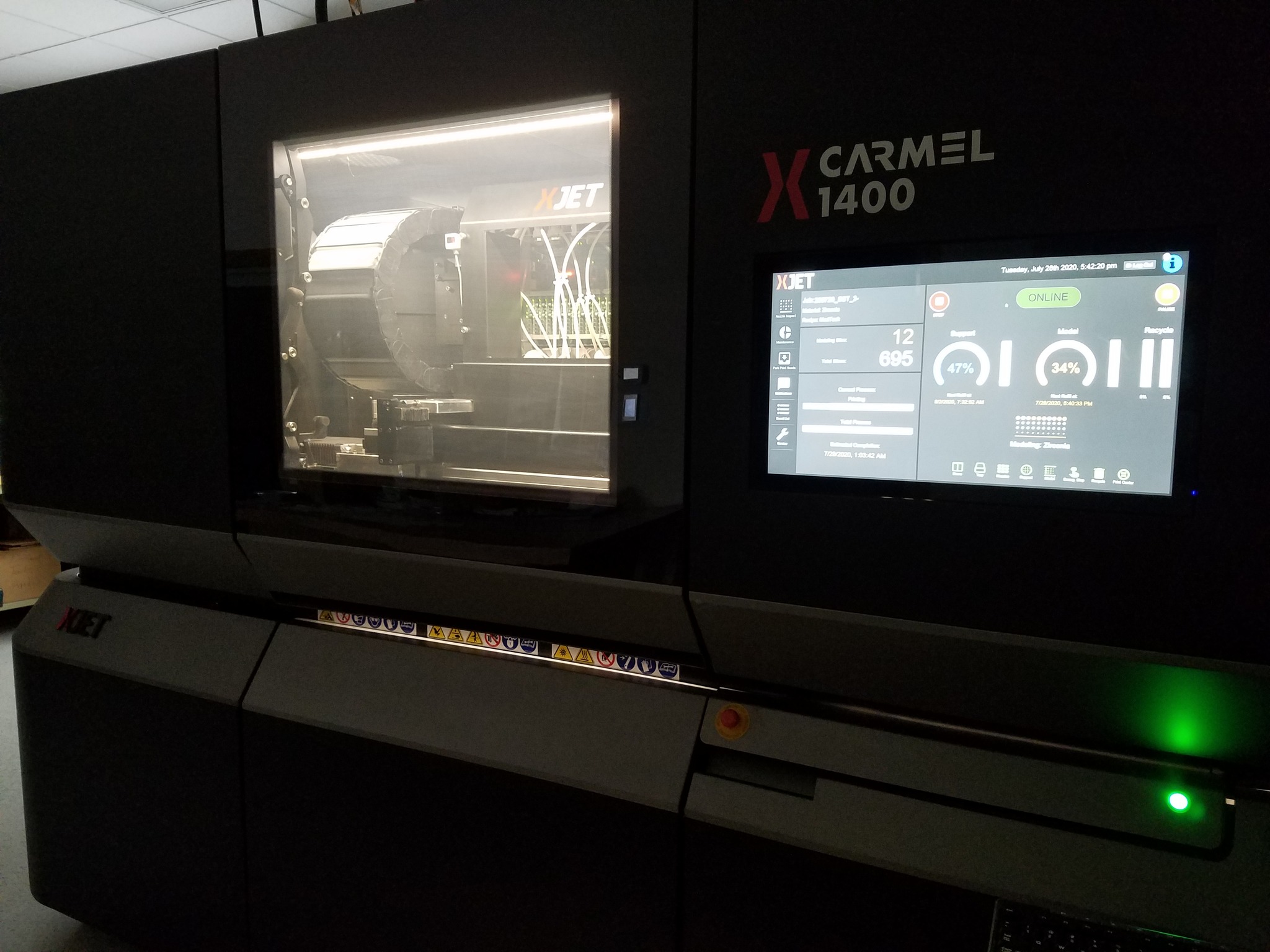

The XJet Carmel 1400C 3D printer is the state-of-the-art platform for high-precision additive manufacturing of advanced technical ceramics. Featuring XJet’s NanoParticle Jetting™ (NPJ™) technology, the XJet Carmel 1400C 3D printer offers a breakthrough in AM/3DP precision and efficiency. As an experienced contract manufacturer of custom advanced technical ceramics, Marvel Medtech Advanced Manufacturing has developed unique expertise in using the XJet Carmel 1400C 3D printer and delivered hundreds of custom ceramic parts with complex part geometries and demanding design details across a variety of industry sectors. We take pride in our investment and our expertise that allows us to assure the fastest turnaround times without compromising on quality.

Features of the XJet Carmel 1400C 3D Printer

The XJet Carmel 1400C 3D printer offers the following features and capabilities:

- Large build volume: 14cm W x 50cm L x 20cm D

- Ultra-thin (10 micron) build layer thickness

- 24 High-Precision Print Heads each with 512 inkjet nozzles

- Three-level Ink Delivery System (IDS) for managing ink recirculation with continuous mixing and recycling to ensure ceramic nanoparticles remain suspended and blended

- Large touchscreen UI for easily monitoring and controlling all aspects of printer operations

- Automated functions for monitoring and controlling/calibrating print layer thickness, in-process print head purging, subsystem cleaning, dust and fume collection

- Customizable “Recipes” for fine-tuning printing parameters based on specific part optimization needs

- Continuous data collection and error monitoring; auto pause on error detection; auto-recovery capabilities; auto-stop functionality

- Ink volume monitoring and reporting

XJet Carmel 1400C 3D Printer System Specifications

| System Specifications | |

| Build Area (LxW) of Removable Build Tray | 500mm x 140 mm (19.7x 5.5 inch) |

| Layer Thickness | 10 microns |

| Building Speed | Up to 1 mm height per hour |

| Dimensions ( wxdxh) | 310 x 212 x 185 cm/ 122 x 84 x 73 inch |

| Weight | 3 tons, 6,614 lb |

| Operating Environment | 18°-25°C; 64°-77°F; <50% relative humidity |

| Regulations Conformity | CE; FCC; UL |

| Materials | |

| Materials | Alumina, Zirconia Ceramics

Water-Soluble support material |

| Part Quality | |

| Accuracy | 20-50 microns on dimensions < 50mm

100 microns on dimensions >50 mm |

| Minimum Hole Size | 200 microns |

| Minimum Wall Thickness | 100 microns |

| Density | Zirconia: >6.02 g/cm3 (>99.5%) Alumina: 3.93 g/cm3 (>99.5%) |

| Flexural Strength | Zirconia > 830 MPa

Zirconia > 400 MPa |

| Surface Roughness | N7-N9 |

| Shrinkage (isotropic and linear) | Alumina: 14.5%

Zirconia: 17.8% |

| Other Specifications | |

| Air Pressure Required | 6 bar |

| Electrical Power Consumption | 220V, 3x 32A, 14 kW |

Note: The above measurements are based on testing conducted in XJet labs. The part quality specifications may change slightly depending on geometry, model orientation, and build parameters. All these measurements are according to ISO 18754 and ASTM C1161.

Applications

The exclusive capabilities of the XJet Carmel 1400C 3D printer system and Marvel Medtech Advanced Manufacturing’s advanced technical ceramics AM/3DP expertise are ideal for demanding applications in medical/healthcare, aerospace/defense, energy, electrical/electronics, automotive/transportation, consumer products and many other applications.

Please contact our team today with your questions on how the state-of-the-art XJet Carmel 1400C 3D printer technology can respond to your needs for advanced technical ceramics applications. Call us at 1-877-345-6261 or 1-608-688-0868, or complete our Contact Us form. You may also Request a Quote for Your Project to receive a secure file upload link.